产品特点

高精度ER筒夹刀柄通常用于需要高精度和可靠性的加工场景。以下是一些主要的应用场景:

精密零件加工:ER筒夹刀柄适用于需要高精度加工的领域,如医疗器械、精密仪器等,能够确保加工精度和表面质量。

模具加工:在制造模具和模型时,ER筒夹刀柄可以提供强大而稳定的刀具夹持,适用于对尺寸精度和表面光洁度要求高的加工任务。

微孔加工:对于微孔加工,ER筒夹刀柄能够提供较高的刚性和精度,确保微小孔径的准确性和加工质量。

高速切削:在高速切削环境下,ER筒夹刀柄能够提供稳定可靠的刀具夹持,降低振动和提高加工效率。

需频繁更换刀具的加工:由于ER筒夹式刀柄具有方便快捷的刀具更换特性,适用于需要频繁更换刀具的加工场景,提高生产效率。

产品范围

高精度ER筒夹刀柄

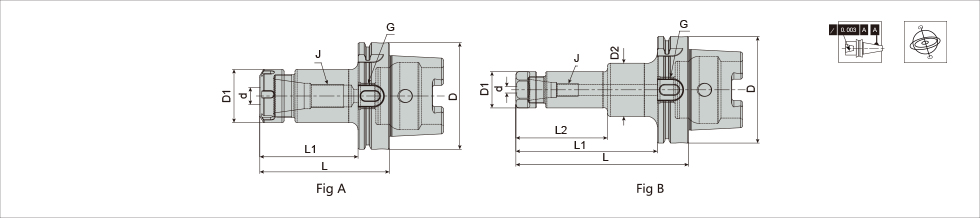

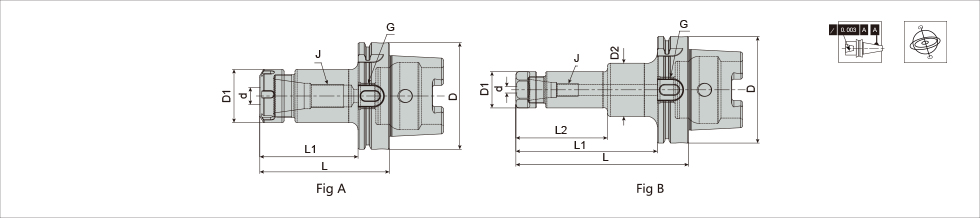

| 规格型号 | L | L1 | L2 | D | D1 | D2 | d | J | Fig | G | Kg |

| HSK A50 ER16x100.TOP(1) | 100 | 74 | - | 50 | 28 | - | 0.5-10 | M10 | A | M16x1 | 0.62 |

| HSK A50 ER20x100.TOP(1) | 100 | 74 | - | 50 | 34 | - | 1-13 | M12 | A | M16x1 | 0.7 |

| HSK A50 ER25x100.TOP(1) | 100 | 74 | 28.5 | 50 | 42 | 41.8 | 1-16 | M16 | B | M16x1 | 0.84 |

| HSK A50 ER32x100.TOP(1) | 100 | 74 | 31 | 50 | 50 | 40.4 | 2-20 | M22x1.5 | B | M16x1 | 0.76 |

| HSK A63 ER16x100.TOP(1) | 100 | 74 | - | 63 | 28 | - | 0.5-10 | M10 | A | M18x1.0 | 0.8 |

| HSK A63 ER16x120.TOP(1) | 120 | 94 | - | 63 | 28 | - | 0.5-10 | M10 | A | M18x1.0 | 1 |

| HSK A63 ER16x160.TOP(1) | 160 | 134 | 85.6 | 63 | 28 | 40 | 0.5-10 | M10 | B | M18x1.0 | 1.4 |

| HSK A63 ER20x100.TOP(1) | 100 | 74 | - | 63 | 34 | - | 1-13 | M12 | A | M18x1.0 | 0.9 |

| HSK A63 ER20x120.TOP(1) | 120 | 94 | - | 63 | 34 | - | 1-13 | M12 | A | M18x1.0 | 1.1 |

| HSK A63 ER20x160.TOP(1) | 160 | 134 | 85 | 63 | 34 | 45 | 1-13 | M12 | B | M18x1.0 | 1.6 |

| HSK A63 ER25x80.TOP(1) | 80 | 54 | - | 63 | 42 | - | 1-16 | M8 | A | M18x1.0 | 0.9 |

| HSK A63 ER25x100.TOP(1) | 100 | 74 | - | 63 | 42 | - | 1-16 | M16 | A | M18x1.0 | 1.1 |

| HSK A63 ER25x120.TOP(1) | 120 | 94 | - | 63 | 42 | - | 1-16 | M16 | A | M18x1.0 | 1.3 |

| HSK A63 ER25x160.TOP(1) | 160 | 134 | - | 63 | 42 | - | 1-16 | M16 | A | M18x1.0 | 1.7 |

| HSK A63 ER32x80.TOP(1) | 80 | 54 | 31 | 63 | 50 | 40.4 | 2-20 | M22x1.5 | B | M18x1.0 | 0.8 |

| HSK A63 ER32x100.TOP(1) | 100 | 74 | - | 63 | 50 | - | 2-20 | M22x1.5 | A | M18x1.0 | 1.2 |

| HSK A63 ER32x120.TOP(1) | 120 | 94 | - | 63 | 50 | - | 2-20 | M22x1.5 | A | M18x1.0 | 1.5 |

| HSK A63 ER32x160.TOP(1) | 160 | 134 | - | 63 | 50 | - | 2-20 | M22x1.5 | A | M18x1.0 | 2 |

| HSK A63 ER40x80.TOP(1) | 80 | 54 | 34 | 63 | 63 | 50.4 | 3-26 | - | B | M18x1.0 | 0.9 |

| HSK A63 ER40x100.TOP(1) | 100 | 74 | 34 | 63 | 63 | 50.4 | 3-26 | M28x1.5 | B | M18x1.0 | 1.2 |

| HSK A63 ER40x120.TOP(1) | 120 | 94 | 34 | 63 | 63 | 50.4 | 3-26 | M28x1.5 | B | M18x1.0 | 1.4 |

| HSK A100 ER16x100.TOP(2) | 100 | 71 | - | 100 | 28 | - | 0.5-10 | M10 | A | M24x1.5 | 2.2 |

| HSK A100 ER16x160.TOP(2) | 160 | 131 | 85 | 100 | 28 | 40 | 0.5-10 | M10 | B | M24x1.5 | 2.7 |

| HSK A100 ER20x100.TOP(2) | 100 | 71 | - | 100 | 34 | - | 1-13 | M12 | A | M24x1.5 | 2.3 |

| HSK A100 ER20x160.TOP(2) | 120 | 131 | 85 | 100 | 34 | 50 | 1-13 | M12 | B | M24x1.5 | 3.1 |

| HSK A100 ER25x100.TOP(2) | 100 | 71 | - | 100 | 42 | - | 1-16 | M16 | A | M24x1.5 | 2.5 |

| HSK A100 ER25x120.TOP(2) | 120 | 91 | - | 100 | 42 | - | 1-16 | M16 | A | M24x1.5 | 2.7 |

| HSK A100 ER25x160.TOP(2) | 160 | 131 | - | 100 | 42 | - | 1-16 | M16 | A | M24x1.5 | 3.1 |

| HSK A100 ER32x100.TOP(2) | 100 | 71 | - | 100 | 50 | - | 2-20 | M22x1.5 | A | M24x1.5 | 2.5 |

| HSK A100 ER32x120.TOP(2) | 120 | 91 | - | 100 | 50 | - | 2-20 | M22x1.5 | A | M24x1.5 | 2.8 |

| HSK A100 ER32x160.TOP(2) | 160 | 131 | - | 100 | 50 | - | 2-20 | M22x1.5 | A | M24x1.5 | 3.3 |

| HSK A100 ER40x100.TOP(2) | 100 | 71 | - | 100 | 63 | - | 3-26 | M28x1.5 | A | M24x1.5 | 2.8 |

| HSK A100 ER40x120.TOP(2) | 120 | 91 | - | 100 | 63 | - | 3-26 | M28x1.5 | A | M24x1.5 | 3.2 |

| HSK A100 ER40x160.TOP(2) | 160 | 131 | - | 100 | 63 | - | 3-26 | M28x1.5 | A | M24x1.5 | 4.1 |

●内冷却管需单独订购。

●⑴当工作转速N=20000RPM时,刀柄的平衡等级为G2.5,

⑵当工作转速N=12000RPM时,刀柄的平衡等级为G6.3

孔加工刀具

孔加工刀具 阻尼减振刀具

阻尼减振刀具 铣削刀具

铣削刀具 刀柄系统

刀柄系统 硬质合金刀具

硬质合金刀具 车削刀具

车削刀具 附件

附件

刀具

刀具 联系松德

联系松德 简体中文

简体中文 English

English