产品特点

●镗孔范围:Φ20~Φ153

●双刃可调,可实现双刃、单刃和错齿镗削

●矩形槽结构可以传递大扭矩

●刀座锁紧采用蝶形弹垫预紧,方便调整

●适合稳定工况加工

产品范围

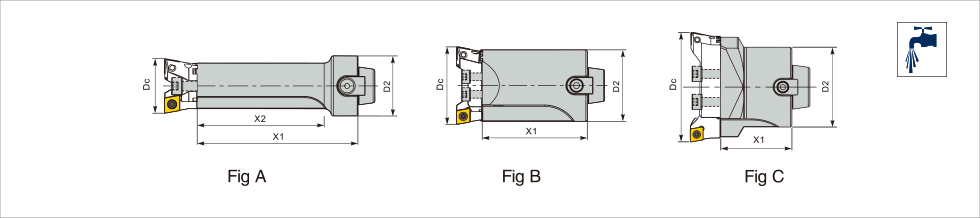

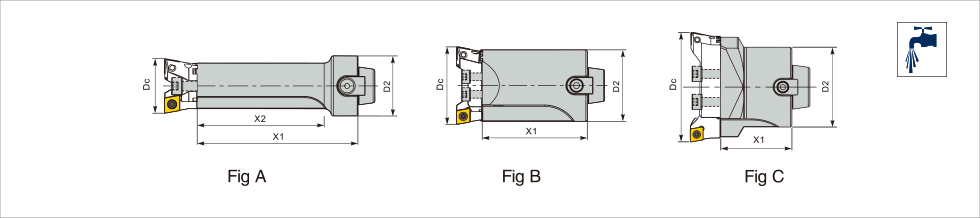

BR系列粗镗刀

| 规格型号 | Dc | D2 | X1 | X2 | Z | Fig | Kg | 适配刀座 |

| BR D020-027.E25.Z2.68.C | 20-24 | 25 | 68 | 55 | 2 | A | 0.14 | S..D020-024.. |

| 23-27 | 25 | 68 | 55 | 2 | A | 0.14 | S..D023-027.. |

| BR D020-027.E25.Z2.88.C | 20-24 | 25 | 88 | 75 | 2 | A | 0.15 | S..D020-024.. |

| 23-27 | 25 | 88 | 75 | 2 | A | 0.15 | S..D023-027.. |

| BR D026-035.E25.Z2.68.C | 26-35 | 25 | 68 | - | 2 | B | 0.2 | S..D026-035.. |

| BR D033-041.E32.Z2.68.C | 33-41 | 32 | 68 | - | 2 | B | 0.35 | S..D033-041.. |

| BR D041-055.E40.Z2.65.C | 41-55 | 40 | 65 | - | 2 | B | 0.54 | S..D041-055.. |

| BR D055-070.E50.Z2.75.C | 55-70 | 50 | 75 | - | 2 | B | 0.98 | S..D055-070.. |

| BR D070-090.E63.Z2.75.C | 70-90 | 63 | 75 | - | 2 | B | 1.65 | S..D070-090.. |

| BR D090-110.E63.Z2.75.C | 90-110 | 63 | 75 | - | 2 | C | 1.9 | S..D090-110.. |

| BR D090-110.E80.Z2.75.C | 90-110 | 80 | 75 | - | 2 | B | 2.68 | S..D090-110.. |

| BR D110-153.E63.Z2.75.C | 110-133 | 63 | 75 | - | 2 | C | 2.2 | S..D110-133.. |

| 130-153 | 63 | 75 | - | 2 | C | 2.2 | S..D130-153.. |

| BR D110-153.E80.Z2.75.C | 110-133 | 80 | 75 | - | 2 | C | 2.94 | S..D110-133.. |

| 130-153 | 80 | 75 | - | 2 | C | 2.94 | S..D130-153.. |

●适配刀座需单独订购,“请点击此处”

●适配刀柄需单独订购,“请点击此处”

●加工不同材料刀具的切削参数,“请点击此处”

●刀座刻线标注依据:CC06/CC09/TC11/TC16/SO06圆角为R0.4时的值,SO09圆角为R0.6时的值,

CC12/SC09/SC12/SO12圆角为R0.8时的值;SO16圆角为R1.2时的值;

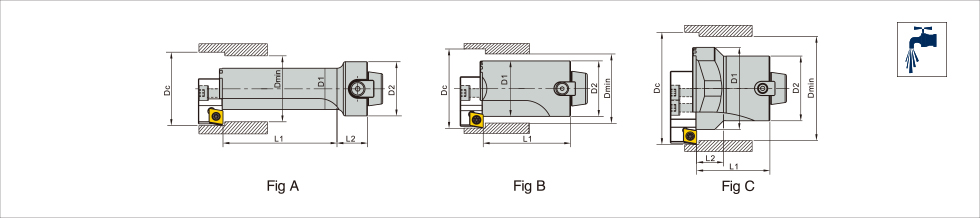

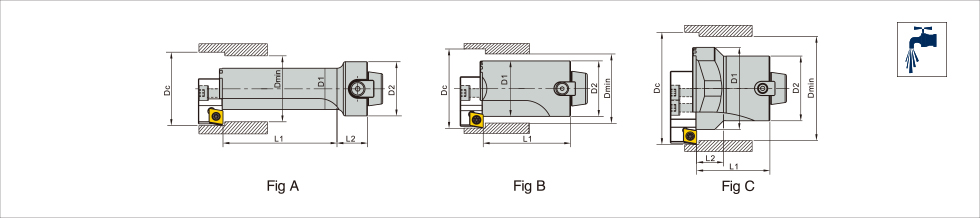

BR系列粗镗刀(反镗示意)

| 规格型号 | Dc | D1 | D2 | L1 | L2 | Z | Fig | Kg | 适配刀座 |

| BR D020-027.E25.Z2.68.C | 30-35 | 19 | 25 | 52 | 14 | 1 | A | 0.15 | S90C D19.3035.CC06 |

| BR D020-027.E25.Z2.88.C | 30-35 | 19 | 25 | 72 | 14 | 1 | A | 0.15 | S90C D19.3035.CC06 |

| BR D026-035.E25.Z2.68.C | 33-41 | 25 | 25 | 65 | - | 1 | B | 0.22 | S90C D25.3341.CC06 |

| 40-48 | 25 | 25 | 65 | - | 1 | B | 0.21 | S90C D25.4048.CC06 |

| BR D033-041.E32.Z2.68.C | 42-52 | 32 | 32 | 65 | - | 1 | B | 0.38 | S90C D32.4252.CC06 |

| 51-61 | 32 | 32 | 65 | - | 1 | B | 0.37 | S90C D32.5161.CC06 |

| BR D041-055.E40.Z2.65.C | 53-65 | 40 | 40 | 62 | - | 1 | B | 0.61 | S90C D40.5365.CC09 |

| 64-76 | 40 | 40 | 62 | - | 1 | B | 0.6 | S90C D40.6476.CC09 |

| BR D055-070.E50.Z2.75.C | 53-69 | 50 | 50 | 72 | - | 1 | B | 1.04 | S90C D50.5369.CC09 |

| 68-84 | 50 | 50 | 72 | - | 1 | B | 1.06 | S90C D50.6884.CC09 |

| 83-99 | 50 | 50 | 72 | - | 1 | B | 1.08 | S90C D50.8399.CC09 |

| BR D070-090.E63.Z2.75.C | 68-89 | 63 | 63 | 70 | - | 1 | B | 1.81 | S90C D63.6889.CC09 |

| 88-109 | 63 | 63 | 70 | - | 1 | B | 1.77 | S90C D63.88109.CC09 |

| BR D090-110.E63.Z2.75.C | 88-110 | 80 | 63 | 70 | 26 | 1 | C | 2.21 | S90C D80.88110.CC12 |

| 108-130 | 80 | 63 | 70 | 26 | 1 | C | 1.72 | S90C D80.108130.CC12 |

| BR D090-110.E80.Z2.75.C | 88-110 | 80 | 80 | 70 | - | 1 | B | 2.99 | S90C D80.88110.CC12 |

| 108-130 | 80 | 80 | 70 | - | 1 | B | 2.92 | S90C D80.108130.CC12 |

| BR D110-153.E63.Z2.75.C | 108-132 | 100 | 63 | 70 | 26 | 1 | C | 2.55 | S90C D100.108132.CC12 |

| 128-152 | 100 | 63 | 70 | 26 | 1 | C | 2.48 | S90C D100.128152.CC12 |

| BR D110-153.E80.Z2.75.C | 108-132 | 100 | 80 | 70 | 23 | 1 | C | 3.31 | S90C D100.108132.CC12 |

| 128-152 | 100 | 80 | 70 | 23 | 1 | C | 3.24 | S90C D100.128152.CC12 |

●适配刀座需单独订购,“请点击此处”

●适配刀柄需单独订购,“请点击此处”

●加工不同材料刀具的切削参数,“请点击此处”

●最小过孔直径Dmin=(Dc+D1)/2+1。

●刀座刻线标注依据:CC06/CC09/TC11/TC16/SO06圆角为R0.4时的值,SO09圆角为R0.6时的值,

CC12/SC09/SC12/SO12圆角为R0.8时的值;SO16圆角为R1.2时的值;

孔加工刀具

孔加工刀具 阻尼减振刀具

阻尼减振刀具 铣削刀具

铣削刀具 刀柄系统

刀柄系统 硬质合金刀具

硬质合金刀具 车削刀具

车削刀具 附件

附件

刀具

刀具 联系松德

联系松德 简体中文

简体中文 English

English