刀具

孔加工刀具

孔加工刀具 阻尼减振刀具

阻尼减振刀具 铣削刀具

铣削刀具 刀柄系统

刀柄系统 硬质合金刀具

硬质合金刀具 车削刀具

车削刀具 附件

附件

孔加工刀具

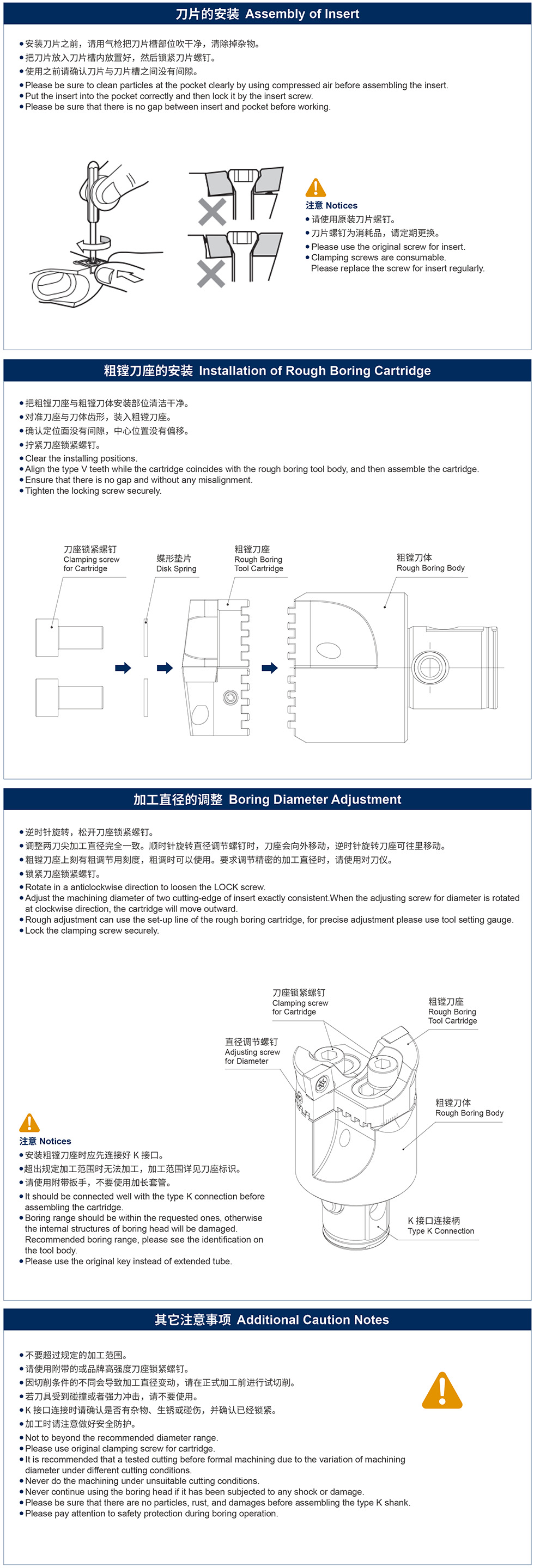

- 粗镗刀具

- 精镗刀具

- 镗刀系统

- 镗削刀夹

- 钻削

- 自动伸缩式反刮刀

- 镗刀片

- 阻尼减振车刀

- 阻尼减振镗刀

- 阻尼减振铣刀杆

- 阻尼减振刀具非标定制

- 可调式端面槽铣刀

- 可转位倒角刀

- 可转位立铣刀

- 可转位面铣刀

- 三面刃铣刀

- 模块式刀柄接杆

- DIN69871-A

- HSK-A

- HSK-T

- MAS403 BT

- PSC

- 整体硬质合金铰刀系列

- 整体硬质合金立铣刀系列

- 整体硬质合金钻头系列

- 外圆车削刀具

- 车刀片

- 内孔车刀定位座

- 内孔车削刀具

- 套筒

- 附件

刀具

刀具 联系松德

联系松德 简体中文

简体中文 English

English